In the race towards more efficient and sustainable vehicles, thermal management systems have emerged as a critical frontier where artificial intelligence is driving unprecedented innovation. Modern vehicles, from electric cars to traditional combustion engines, generate complex thermal patterns that directly impact performance, safety, and longevity. AI-powered thermal management systems are revolutionizing how we monitor, predict, and control temperature distributions across vehicle components, leading to significant improvements in energy efficiency and overall vehicle performance.

These intelligent systems leverage machine learning algorithms to analyze real-time data from thousands of sensors, creating dynamic thermal profiles that adapt to changing driving conditions. By precisely balancing heating and cooling needs across different vehicle subsystems, AI-enhanced thermal management reduces energy consumption while extending component life spans. This technology has become particularly crucial for electric vehicles, where battery temperature regulation directly affects range, charging speed, and long-term reliability.

As automotive manufacturers increasingly integrate AI capabilities into their thermal management solutions, we’re witnessing a transformation in how vehicles maintain optimal operating temperatures. The integration of predictive analytics and smart control systems isn’t just improving current vehicle performance – it’s paving the way for the next generation of autonomous and electric vehicles that will require even more sophisticated thermal management solutions.

Why Traditional Vehicle Cooling Systems Fall Short

Current Thermal Management Challenges

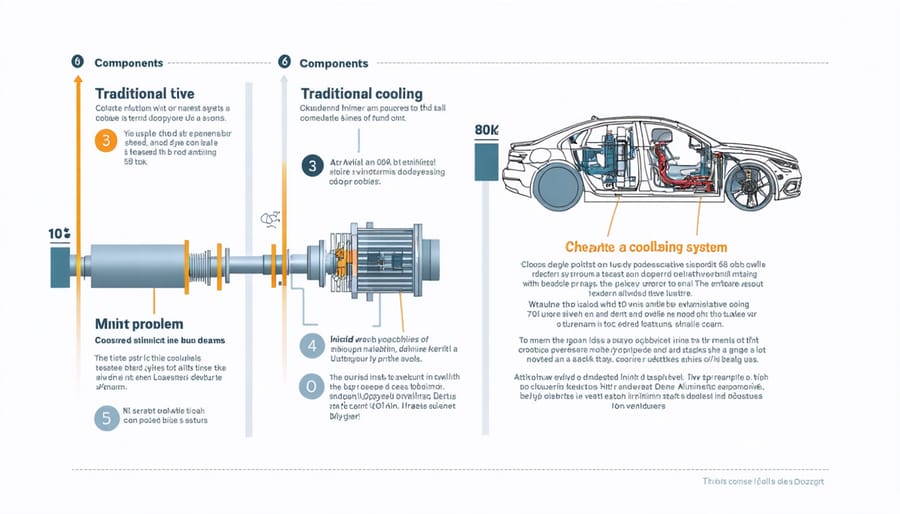

Traditional vehicle thermal management systems face several critical challenges that impact both performance and efficiency. The most pressing issue is the system’s inability to adapt quickly to varying operating conditions, leading to either overcooling or insufficient cooling at crucial moments. This results in unnecessary energy consumption and potential component stress.

Another significant challenge is the limited coordination between different cooling circuits. Modern vehicles often have separate cooling systems for the engine, transmission, and battery packs, which operate independently rather than as an integrated unit. This lack of synchronization can lead to inefficient energy usage and suboptimal temperature control.

Weight and space constraints also pose considerable problems. Conventional cooling systems require extensive piping, pumps, and heat exchangers, adding substantial mass to the vehicle and occupying valuable space that could be used for other components. Additionally, these systems often struggle with heat distribution during extreme weather conditions or high-performance situations.

The growing complexity of electric and hybrid vehicles has further complicated thermal management, as battery systems require precise temperature control to maintain optimal performance and longevity. Current systems sometimes struggle to maintain ideal operating temperatures across all components simultaneously.

The Energy Efficiency Problem

Vehicle thermal management directly impacts both performance and fuel efficiency, creating a significant challenge for automotive engineers. When cooling systems operate inefficiently, engines can overheat, leading to reduced power output and potential damage to critical components. Studies show that poor thermal management can increase fuel consumption by up to 5%, as engines must work harder to maintain optimal operating temperatures.

Modern vehicles face additional cooling challenges due to the increasing integration of electronic components and battery systems, particularly in hybrid and electric vehicles. These components generate substantial heat while requiring precise temperature control for optimal performance. Without effective thermal management, battery life can decrease dramatically, and electronic systems may throttle their performance to prevent damage.

The inefficiency problem extends beyond just the engine bay. Climate control systems, which maintain passenger comfort, can consume significant power. In electric vehicles, using the air conditioning system can reduce driving range by up to 17% in hot weather conditions. This creates a complex balancing act between maintaining comfortable cabin temperatures and preserving vehicle range and efficiency. Engineers must constantly innovate to find solutions that address these competing demands while meeting increasingly stringent environmental regulations.

How AI Transforms Vehicle Temperature Control

Smart Sensors and Real-time Monitoring

Modern vehicle thermal management systems rely heavily on AI sensors and sophisticated monitoring tools to maintain optimal performance. These advanced sensors continuously collect data about various thermal parameters, including coolant temperature, engine heat distribution, and ambient conditions, providing a comprehensive view of the vehicle’s thermal state.

Real-time monitoring systems now integrate multiple sensor types, from traditional thermistors to cutting-edge infrared sensors and thermal imaging cameras. These devices work together to create a detailed thermal map of the vehicle, allowing for precise temperature control and early detection of potential issues.

The data collected is processed instantaneously through onboard computers that can detect patterns and anomalies. For instance, if a sudden temperature spike occurs in a specific component, the system can immediately alert the driver and adjust cooling parameters to prevent potential damage.

Smart sensors also adapt to different driving conditions. During high-performance driving, they might increase monitoring frequency and sensitivity, while in normal conditions, they optimize for efficiency. This dynamic adjustment helps balance performance with energy consumption.

The integration of wireless connectivity allows these systems to transmit data to manufacturers and service centers, enabling predictive maintenance and remote diagnostics. This proactive approach helps prevent thermal-related failures before they occur, significantly improving vehicle reliability and longevity.

Predictive Temperature Management

Modern vehicles leverage artificial intelligence to revolutionize how thermal management systems operate, moving from reactive to predictive approaches. Instead of responding only when temperatures reach critical levels, AI algorithms continuously analyze multiple data points to anticipate cooling needs before they become urgent.

These smart systems utilize edge AI processors to process real-time data from various sensors, including engine temperature, ambient conditions, driving patterns, and historical performance metrics. By considering these factors simultaneously, the system can predict when specific components will require additional cooling and adjust accordingly.

For example, when the AI detects that you’re about to climb a steep hill, it can preemptively increase coolant flow to the engine, preventing potential temperature spikes. Similarly, if you’re stuck in stop-and-go traffic on a hot day, the system anticipates increased thermal stress and optimizes cooling distribution across different vehicle systems.

This predictive approach not only prevents overheating but also improves overall efficiency. By anticipating cooling needs, the system can operate more economically, activating cooling components only when necessary and at optimal levels. This results in reduced energy consumption, extended component life, and improved vehicle performance, all while maintaining ideal operating temperatures across all critical systems.

Machine Learning Optimization

Modern vehicle thermal management systems are becoming increasingly sophisticated through the integration of machine learning algorithms. These smart systems continuously collect and analyze data from multiple sensors throughout the vehicle, learning from patterns in temperature fluctuations, energy usage, and environmental conditions.

By processing this real-time information, the system can predict heating and cooling needs before they become critical. For example, if the AI notices that the engine typically requires more cooling during uphill climbs on warm days, it will proactively adjust coolant flow rates and fan speeds to maintain optimal temperature ranges.

The learning capability extends to personalized comfort as well. The system remembers driver preferences and adapts to recurring patterns, such as pre-conditioning the cabin temperature during regular commute times or adjusting thermal distribution based on occupant behavior.

This continuous optimization leads to significant improvements in energy efficiency and component longevity. The AI can fine-tune its responses by analyzing historical performance data, reducing energy waste and preventing unnecessary strain on the cooling system. As these systems gather more data, their prediction accuracy improves, resulting in better thermal management and enhanced vehicle performance.

Real-World Applications and Benefits

Electric Vehicle Range Extension

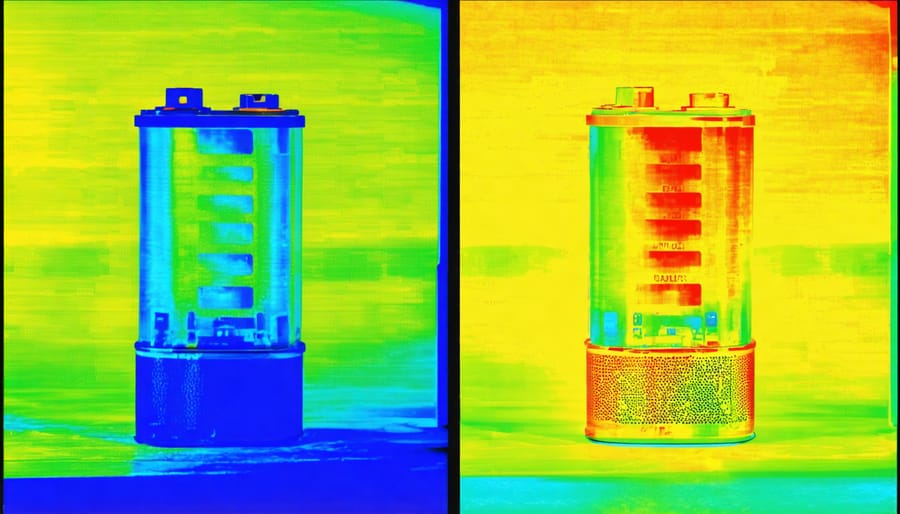

Effective thermal management plays a crucial role in extending the range of electric vehicles, particularly in extreme weather conditions. When batteries operate outside their optimal temperature range (typically between 20-40°C), their efficiency can drop significantly, directly impacting the vehicle’s driving range.

During cold weather, batteries require more energy for both their own heating and powering the cabin heating system. This dual demand can reduce driving range by up to 40% in freezing temperatures. Conversely, high temperatures can accelerate battery degradation and require additional cooling power, which also affects range performance.

Advanced thermal management systems help mitigate these challenges through several strategies. Intelligent battery preconditioning while the vehicle is still plugged in helps achieve optimal operating temperature before driving begins. This practice preserves battery power for actual driving rather than temperature regulation.

Heat pump systems have emerged as a particularly effective solution, recovering waste heat from the powertrain and converting it into useful energy for cabin heating. This approach is up to three times more efficient than traditional resistive heating, significantly reducing the energy drain on the battery.

Some cutting-edge thermal management systems also incorporate phase-change materials that absorb excess heat during high-load conditions and release it when needed, helping maintain stable battery temperatures. Additionally, smart thermal management algorithms can predict heating and cooling needs based on driving patterns, weather forecasts, and route information, optimizing energy usage throughout the journey.

These improvements in thermal management technology have helped modern electric vehicles achieve more consistent range performance across varying weather conditions, making them more reliable for everyday use.

Performance Vehicle Applications

In high-performance and racing vehicles, thermal management becomes critical due to the extreme conditions these machines encounter. Racing engines can generate temperatures exceeding 200°F (93°C) under sustained high-speed operation, making efficient cooling essential for maintaining peak performance and preventing engine failure.

Advanced thermal management systems in performance vehicles often incorporate multiple cooling circuits, with separate systems for the engine, transmission, and brake systems. These sophisticated setups allow for precise temperature control across different vehicle components, optimizing performance while preventing thermal-induced stress and wear.

For racing applications, thermal management systems frequently include features like dual radiators, oil coolers, and brake cooling ducts. Many professional racing teams employ real-time temperature monitoring systems that provide instant feedback to drivers and pit crews, allowing for strategic adjustments during races.

Modern performance vehicles also benefit from adaptive cooling systems that can adjust their operation based on driving conditions. During high-speed track runs, these systems can maximize cooling capacity, while during normal street driving, they can optimize for efficiency and reduced drag.

The integration of lightweight materials and aerodynamic design elements further enhances thermal management effectiveness. Carbon fiber ducting, ceramic coatings, and heat-reflective materials are commonly used to direct airflow and manage heat dissipation, contributing to both performance and reliability in demanding racing conditions.

Commercial Fleet Management

Commercial fleet operators face unique challenges in managing vehicle thermal systems across large numbers of trucks, buses, and delivery vehicles. Modern fleet management solutions integrate sophisticated thermal monitoring and control systems to optimize performance while reducing operational costs. AI-powered cooling systems are particularly valuable in this context, helping fleet managers make data-driven decisions about maintenance and energy efficiency.

These systems collect real-time temperature data from multiple points throughout each vehicle, including engine compartments, cargo areas, and cabin spaces. This information feeds into centralized management platforms that track thermal patterns across entire fleets. Fleet managers can identify potential issues before they become serious problems, schedule predictive maintenance, and optimize routes based on environmental conditions.

For refrigerated transport vehicles, thermal management is especially critical. Advanced systems maintain precise temperature control for sensitive cargo while minimizing energy consumption. Smart algorithms adjust cooling power based on factors like outdoor temperature, door openings, and load conditions, ensuring both product safety and fuel efficiency.

The implementation of fleet-wide thermal management systems has shown impressive results. Companies report fuel savings of up to 15% through optimized temperature control, reduced idle time, and better maintenance scheduling. Additionally, these systems help extend vehicle life spans by preventing heat-related damage and ensuring components operate within ideal temperature ranges. This comprehensive approach to thermal management has become essential for modern fleet operations, particularly as environmental regulations and efficiency standards become more stringent.

Future Developments and Integration

The future of vehicle thermal management systems is poised for significant transformation, driven by emerging technologies and the growing demand for energy-efficient smart systems. One of the most promising developments is the integration of predictive AI algorithms that can anticipate thermal loads before they occur, allowing for proactive temperature management and improved efficiency.

Advanced sensor networks combined with machine learning are expected to enable real-time optimization of cooling systems, reducing energy consumption while maintaining optimal operating temperatures. These systems will likely incorporate weather forecasting data and route information to prepare vehicles for upcoming environmental challenges.

Electric vehicles are driving innovation in thermal management, with new solutions focusing on battery temperature control and heat recovery systems. Future developments include smart materials that can automatically adjust their thermal properties and multi-zone cooling systems that can independently manage different vehicle components.

Integration with connected vehicle infrastructure will allow thermal management systems to communicate with smart cities and other vehicles, creating a network of thermally optimized transportation. This connectivity will enable better energy management across entire fleets and improve overall system efficiency.

Manufacturers are also exploring sustainable cooling technologies, including phase-change materials and thermoelectric devices, which promise to revolutionize how we approach vehicle thermal management in the coming years.

The integration of AI in vehicle thermal management systems represents a significant leap forward in automotive technology. As vehicles become increasingly complex and electrified, smart thermal management solutions are proving essential for optimizing performance, extending battery life, and enhancing passenger comfort. The ability of AI systems to predict, adapt, and respond to changing thermal conditions in real-time has transformed how we approach vehicle cooling and heating challenges.

Looking ahead, we can expect even more sophisticated AI-driven thermal management solutions. Machine learning algorithms will continue to evolve, offering more precise temperature control while reducing energy consumption. The rise of autonomous vehicles and advanced electric platforms will further drive innovation in this field, as thermal management becomes increasingly critical for vehicle reliability and efficiency.

These developments point toward a future where vehicles will not only be smarter in how they operate but also more sustainable and comfortable for users. As AI technology continues to mature, we can anticipate more integrated, efficient, and responsive thermal management systems that will set new standards for vehicle performance and environmental impact.