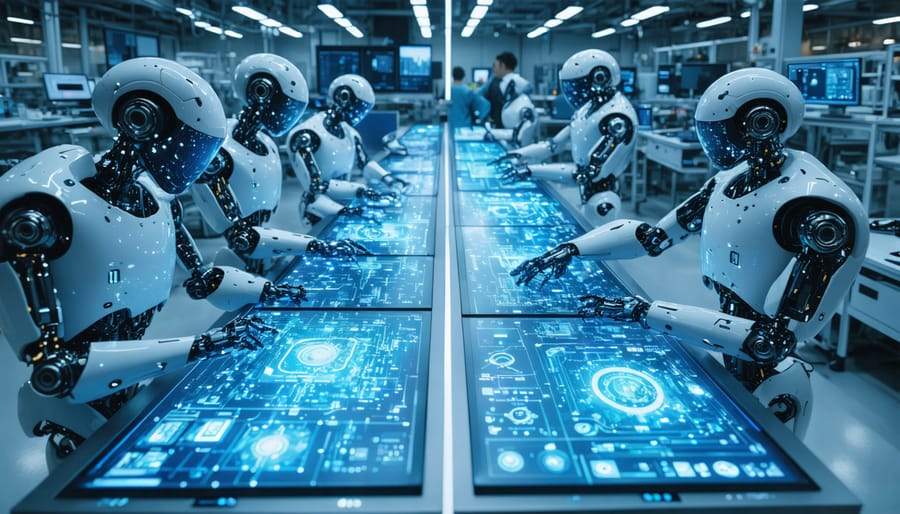

Imagine a future where robots don’t just follow pre-programmed routines but create, learn, and adapt like living beings. This vision is rapidly becoming reality through generative AI robotics, a revolutionary fusion of early AI breakthroughs and modern machine learning capabilities. Unlike traditional robotics, which relies on rigid programming, generative AI enables robots to develop their own solutions to complex challenges, learn from experience, and even improve their physical designs through iterative self-optimization.

As we stand at the threshold of this technological renaissance, generative AI is transforming how robots interact with their environment, solve problems, and assist humans. From manufacturing floors where robots dynamically adapt their assembly processes, to healthcare settings where AI-powered prosthetics learn from their users’ movements, this technology is redefining the boundaries between artificial and human intelligence. The implications are profound: we’re not just programming robots anymore; we’re teaching them to program themselves, opening unprecedented possibilities for innovation and human-machine collaboration.

The Evolution of Robot Programming

Traditional Programming Challenges

Robot programming has historically relied on traditional programming approaches that present significant challenges for developers. These methods typically require extensive manual coding of every possible scenario and movement, making the process time-consuming and prone to errors. Programmers must anticipate all potential situations a robot might encounter, which is nearly impossible in complex, real-world environments.

The rigid nature of conventional programming limits robots’ ability to adapt to unexpected changes or learn from experience. For instance, a traditionally programmed robot in a manufacturing setting might fail completely when encountering slight variations in part positions or lighting conditions. This lack of flexibility often results in costly downtime and the need for frequent reprogramming.

Additionally, traditional methods struggle with tasks requiring complex perception and decision-making. Simple actions that humans perform intuitively, like identifying and picking up objects of varying shapes and sizes, become extremely complicated to program using conventional coding approaches. These limitations have long restricted robots to controlled environments and repetitive tasks, hindering their potential for more dynamic applications.

The AI Programming Breakthrough

The integration of generative AI into robotics marks a revolutionary shift in how robots learn and adapt. Unlike traditional programming methods that rely on rigid, pre-written code, generative AI enables robots to develop their own solutions through experimentation and learning. This breakthrough allows robots to tackle complex tasks without explicit programming for every possible scenario.

Imagine a robot that learns to grasp objects not through thousands of lines of manually written code, but by observing and generating its own understanding of how different shapes and materials should be handled. This is now possible through generative AI models that can create novel movement patterns and problem-solving approaches.

The technology works by training neural networks on vast datasets of robot interactions, enabling them to generate new behaviors autonomously. When faced with an unfamiliar situation, these AI-powered robots can synthesize their learned experiences to create appropriate responses, much like human intuition.

This advancement has dramatically reduced development time and improved robot adaptability. Tasks that once required months of programming can now be learned through generative processes in a fraction of the time, opening new possibilities for robotics applications across industries.

Generative AI’s Impact on Robot Design

Automated Movement Pattern Generation

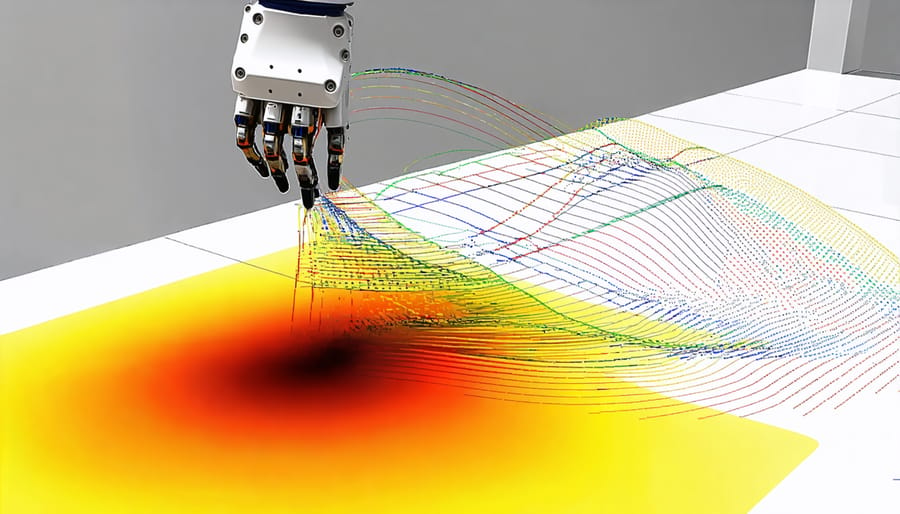

Generative AI has revolutionized how robots learn to move by creating sophisticated movement patterns that adapt to various environments and tasks. Instead of relying on pre-programmed motions, AI systems now analyze vast datasets of successful movements and generate optimal patterns through machine learning algorithms.

The process begins with training the AI on movement data collected from human demonstrations, simulations, and real-world robot experiences. Using techniques like reinforcement learning and neural networks, the system learns to understand the relationship between different joint configurations, environmental factors, and successful task completion.

What makes this approach particularly powerful is its ability to generate novel movement solutions that might not be obvious to human programmers. For instance, a robot tasked with picking up objects can develop multiple approaches based on the object’s shape, weight, and position, automatically adjusting its grip strength and angle of approach.

The AI constantly refines these movements through a feedback loop, where each attempt provides new data for improvement. This iterative process results in increasingly smooth and efficient motions that can be adapted in real-time to handle unexpected situations or changes in the environment.

Modern systems can even share and combine learned movements across different robots, creating a collective knowledge base that accelerates the development of new movement patterns. This collaborative learning approach has significantly reduced the time needed to deploy robots in new applications while improving their overall performance and adaptability.

Adaptive Learning Algorithms

Adaptive learning algorithms represent a groundbreaking approach in generative AI robotics, enabling robots to evolve and improve their behavior through experience. Much like humans learn from trial and error, these algorithms allow robots to adjust their responses based on outcomes and environmental feedback.

The process begins with basic programmed behaviors, but the magic happens when robots start collecting data from their interactions. For example, a warehouse robot might initially struggle with picking up oddly-shaped packages, but through adaptive learning, it gradually refines its grip strength and approach angles based on successful and failed attempts.

These self-improving systems use various techniques, including reinforcement learning, where robots receive “rewards” for successful actions and “penalties” for mistakes. A manufacturing robot might start with a basic understanding of assembly tasks but learn to optimize its movements over time, reducing errors and increasing efficiency.

What makes adaptive learning particularly powerful is its ability to handle unexpected situations. Rather than following rigid programming, robots can develop novel solutions to new challenges. This flexibility is crucial in dynamic environments like healthcare settings, where robots must adapt to different patient needs and unexpected situations.

The technology continues to evolve, with recent developments incorporating neural networks that mimic human brain function, allowing for more sophisticated learning patterns and better decision-making capabilities.

Real-World Applications

Manufacturing Automation

In manufacturing, generative AI is revolutionizing how industrial robots operate and adapt to changing production demands. Traditional robots followed rigid programming, but modern facilities are embracing AI-driven adaptive behaviors that allow machines to learn and optimize their operations in real-time.

Leading automotive manufacturers have implemented generative AI systems that enable robots to automatically adjust their assembly patterns based on different vehicle models coming down the line. These smart systems can generate new movement sequences without human intervention, reducing programming time by up to 60% while maintaining precise quality standards.

Another breakthrough application is in flexible manufacturing cells, where generative AI helps robots adapt to varying product specifications. For instance, a single robot can now handle multiple product variants by generating appropriate gripping patterns and movement paths on the fly. This advancement has particularly benefited electronics manufacturing, where product lifecycles are shorter and production runs more diverse.

Quality control has also seen significant improvements through generative AI integration. Robots equipped with computer vision and generative models can identify defects by comparing products against an ideal template, even detecting subtle variations that might escape human inspection. These systems continuously learn from new examples, improving their accuracy over time.

The integration of generative AI in manufacturing has led to measurable improvements in productivity, with some facilities reporting up to 30% increase in throughput and a 25% reduction in setup times for new production runs. This technology is making automated manufacturing more accessible to small and medium-sized enterprises, as robots become more adaptable and require less specialized programming.

Research and Development

Academic institutions and research laboratories continue to drive innovation in generative AI robotics, building upon a rich research and development history. Leading universities like MIT, Stanford, and Carnegie Mellon are pioneering new approaches to robot learning and adaptation through generative AI models.

These research centers focus on teaching robots to learn from experience and generate novel solutions to unfamiliar challenges. For instance, researchers are developing systems that allow robots to create their own movement patterns by analyzing successful demonstrations, rather than relying on pre-programmed routines.

A significant breakthrough has been the implementation of generative adversarial networks (GANs) in robotics laboratories. These systems enable robots to generate and refine their own training data, significantly reducing the need for extensive human-labeled datasets. This approach has proven particularly valuable in teaching robots to grasp objects of varying shapes and sizes.

Simulation environments play a crucial role in this research, allowing scientists to safely test and iterate generative AI models before deploying them in physical robots. These virtual testing grounds help researchers understand how robots might respond to unexpected situations and generate appropriate responses.

Recent laboratory experiments have demonstrated robots learning to manipulate objects they’ve never encountered before by generating predictions about object properties and appropriate handling techniques. This represents a significant step toward more adaptable and intelligent robotic systems that can operate effectively in unpredictable real-world environments.

Future Implications

Emerging Technologies

The landscape of generative AI robotics is rapidly evolving, with new tools and platforms emerging almost daily. One of the most significant developments is the integration of large language models (LLMs) with robotic control systems, enabling more natural human-robot interactions and improved decision-making capabilities.

Platforms like RosGPT combine the power of OpenAI’s GPT models with the Robot Operating System (ROS), creating a bridge between natural language processing and physical robot control. This allows developers to program robots using conversational commands rather than traditional coding methods.

Simulation environments have also seen remarkable advancement. Tools like Isaac Sim and Nvidia’s Omniverse offer photorealistic virtual testing grounds where robots can learn and develop skills before deployment in the real world. These platforms utilize synthetic data generation to create diverse training scenarios, significantly reducing development time and costs.

Cloud robotics platforms are gaining traction, with services like AWS RoboMaker and Google Cloud Robotics providing scalable solutions for robot development and deployment. These platforms offer pre-built components and APIs that simplify the integration of AI capabilities into robotic systems.

Another noteworthy innovation is the emergence of no-code and low-code platforms for robotics development. These tools democratize access to robotics technology, allowing non-experts to create and deploy AI-powered robotic solutions through intuitive visual interfaces and drag-and-drop components.

Industry Transformation

The integration of generative AI into robotics development is revolutionizing how robots are designed, programmed, and deployed. Traditional robotics development required extensive manual coding and physical prototyping, often taking months or years to create functional systems. Now, generative AI is dramatically accelerating this process through automated design generation and simulation-based testing.

Engineers can now use AI to rapidly prototype robot designs by specifying desired capabilities and constraints, allowing the system to generate optimal configurations. This approach has reduced design iteration cycles from weeks to days, while simultaneously exploring innovative solutions that human designers might not consider.

Machine learning models are also transforming how robots learn to perform tasks. Instead of explicit programming, robots can now learn from demonstrations, simulated environments, and even from their own experiences. This self-learning capability enables robots to adapt to new situations and improve their performance over time, much like human workers.

The manufacturing sector is experiencing particularly significant changes, with generative AI enabling robots to automatically adjust their behavior based on production requirements and environmental conditions. For example, assembly line robots can now generate new movement patterns on the fly to handle product variations without requiring manual reprogramming.

This transformation extends to collaborative robotics, where AI helps robots better understand and interact with human workers. By generating appropriate responses to human actions in real-time, these systems are becoming more intuitive and safer to work alongside, opening new possibilities for human-robot collaboration across industries.

As we’ve explored throughout this article, generative AI is revolutionizing robotics in unprecedented ways. By enabling robots to learn, adapt, and generate novel solutions to complex problems, this technology is breaking down traditional barriers in automation and artificial intelligence. The fusion of generative AI with robotics has already demonstrated remarkable achievements in manufacturing, healthcare, and research laboratories worldwide.

Looking ahead, the future of generative AI robotics appears incredibly promising. We can expect to see more sophisticated robots that can not only learn from their environments but also teach themselves new skills through advanced neural networks and reinforcement learning. The development of more robust and adaptable robotic systems will likely lead to breakthroughs in areas such as disaster response, space exploration, and personalized healthcare.

However, this technological evolution also brings important considerations regarding ethics, safety, and human-robot interaction. As these systems become more autonomous and capable, establishing clear guidelines and frameworks for their deployment will be crucial.

The next decade will likely witness accelerated progress in this field, with improvements in computational power, sensor technology, and AI algorithms driving innovation. For students, professionals, and organizations interested in this space, now is an ideal time to engage with and contribute to this rapidly evolving technology. The convergence of generative AI and robotics isn’t just shaping the future of automation – it’s redefining what’s possible in human-machine collaboration.